Currently Empty: $0.00

Supervision Of Brick Work

Following Points Should be Kept In Mind While Supervising Brick Work :

- The bricks to be used for the site should conform to the specifications laid down by designer.

- For First Class work, the bricks should be sound, hard and well burnt.

- Bricks should be of uniform size and shape, with plane surfaces.

- The bricks should be soaked in water before use for a period for the water to just penetrate the whole depth of bricks.

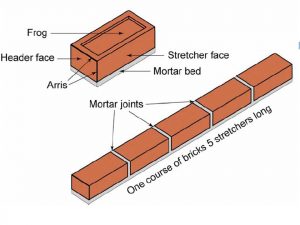

- Bricks should be so laid that the frog is on the top surface and mortar should complete all the beds and sides.

- The mortar to be used should be used of specified quality. Old Mortar should not be used.

- Iron fixtures such as hold fasts for doors etc. should be embedded in cement mortar or in cement concrete

Field Tests On Bricks to Check Quality of Bricks at Site :

- Struck Test : When you strike two bricks together along the longer edges it should produce clear metallic or clear ringing sound.

- Drop Test : When a brick is dropped from certain height of 1m on a levelled surface it shouldn’t be broken down in to pieces which depicts the toughness of the brick.

- Scratch Test: When a scratch is made on the surface of the brick ; any impression on the nail shouldn’t be produced.

- Water Absorption Test : A first class brick should have water absorption is less than 20% otherwise it will absorb water from mortar causes crack in it.

- Efflorescence Test : When bricks are soaked in water and dried it must not develop white patches or white deposits on its surface. These bricks are considered good bricks. The phenomenon of formation of white patches is called Efflorescence.

- Structure Test :Break down a randomly selected brick in half and check if it’s homogeneous and free from any lumps, holes or defects. Cracks and holes in bricks indicate low quality.

e it, then start writing!

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.